An ISO

9001:2015

Certified Company

Auto Bag Filling Machine single line Linear Model

- The Auto Pouch Bag filler is a novel design to mechanise the end of line packaging process of the pouches coming from a vertical form filling and sealing machine ( VFFS )

- The pouches from the VFFS machine is elevated through a cleated elevating conveyor

- Inline pressure testing conveyor kept above the elevating conveyor is used to check the leakages of the pouches coming

- out of the VFFS machine

- This bag filler has only one station that is only the filling station

- Manually bag need to be hold .

- The pouches are counted as per the set value

- After the count the counted pouches are sent to the Bag which is being hold up Manually

- This system Is programmed using PLC

- Ensures complete safety of the operators

AUTO BAGGING SYSTEM

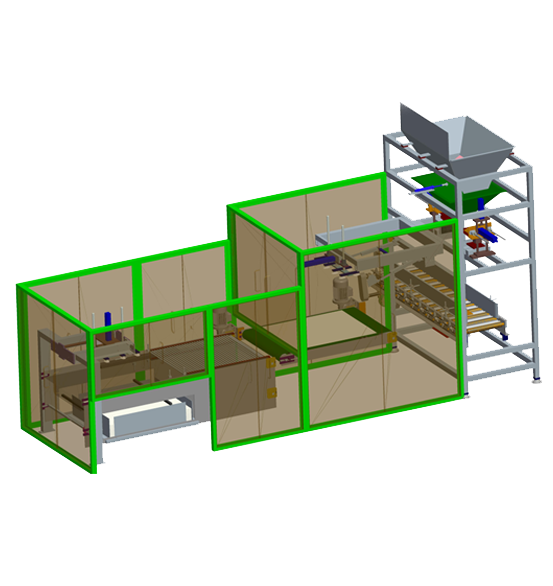

FULLY AUTOMATIC BAG FILLER AND STITCHING MACHINE (AT-BG-STCT)

Purpose :

The fully automatic bag filler is used in the end of line packaging and secondary packaging applications. The machine is used to open the HDPE / Paper bags to open automatically, fill the products and stitch online.

The Scheme of operation :

- The bags are to be stacked on the specially designed bag loading station

- Based on the cycle start and pulse input, the bags are automatically opened through a combination of Vacuum suction cups and grippers

- Opened bags are lifted and loaded to the filling station with mechanical grippers

- Products from inline are counted / weighed and filled into the bags

- For counting option specially designed through beam sensors are provided

- Depending upon the set count the products are counted and filled into the bags accurately

- Once the bag is filled a specially desgined mechanical grippers will pull to the stitching station

- At stitching station, the bags is flattened and fed for proper stitching

- Auto stitching machine stitches the bag and fed to the end of line conveyor

Techncial Specifications :

- All product contact parts are made of SS 304

- Base structure is made of SS 202

- Heavy metal components of non-contact in nature is of carbon steel

- PLC Controlled with HMI display

- Make of PLC : Allen Bradley / Omron / Delta

- Pneumatics : Festo / SMC

- Geared motors : Bonfiglioli / MGM – Varvel

- Air Consumption : 30 CFM

- Safety guards with Schmersel interlock switches