An ISO

9001:2015

Certified Company

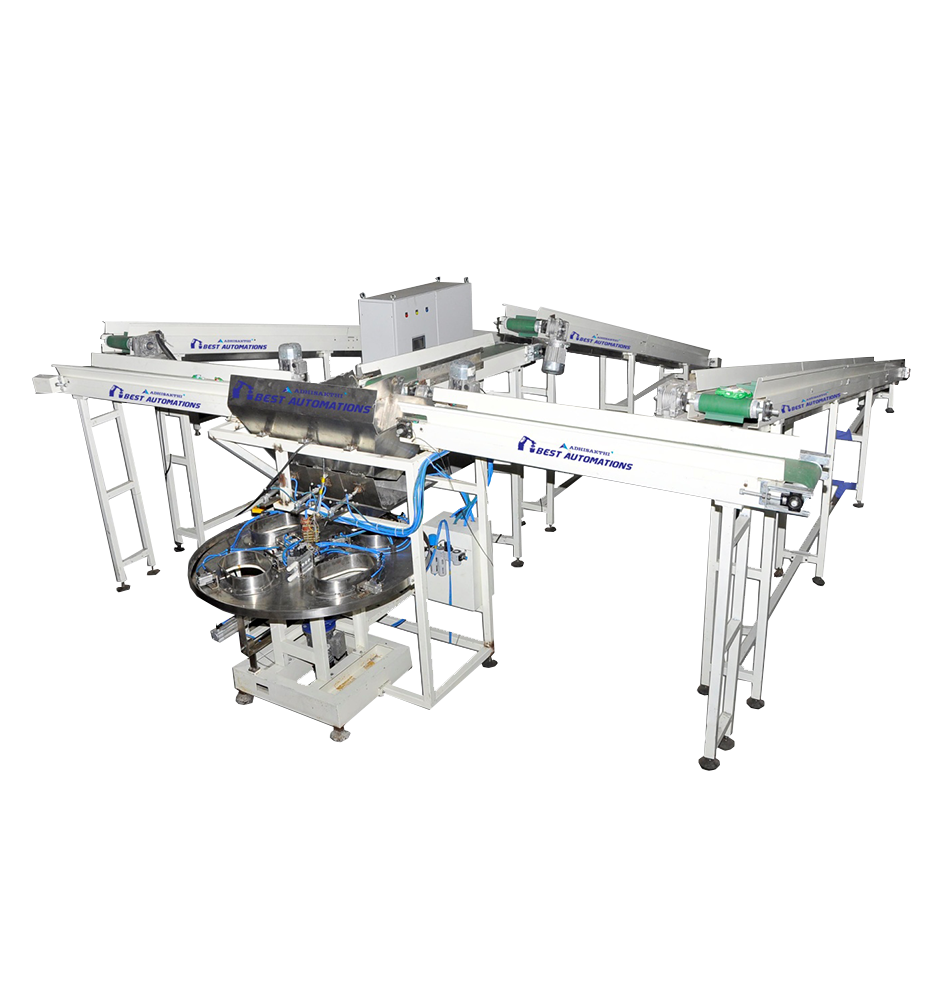

Auto Bag Filling Machine triple line Single Rotary Turret Model

AUTO BAG FILLING SYSTEM-SPECIAL WITH ADDITIONAL FEATURES

- The pouches from the pouch machine will be taken up through horizontal and elevating conveyor

- Pouches are counted using sensors with horizontal conveyor

- Preset quantity of pouches will be received in the counting bin with pneumatic shutters

- Bags are loaded to rotary indexing table fitted with suitable pneumatic clamps

- The counted quantity of pouches is loaded to the bags at the bag filling station

- After filling the bags are released to the discharge conveyor

- Pneumatic components: FESTO

- PLC: ALLENBRABLEY / OMRON

- Base construction : Sturdy MS based frame suitably powder coated

- The machine will have necessary safety interlocks

- Four station holding bag holding system

- The brake mechanism of the pouch packer will be strengthened

- A PLC logic will be built up such that the counting conveyor and inclined conveyor speed shall be regulated at the time of bags are about to get filled to eliminate pouch getting in between the shutters.

- Speed: 6 Bags/Min. It will vary depends upon pouch Qty & pouch gramage.

ADDITIONAL FEATURES INCLUDED:

- Allen bradley make VFD for machine & pouch counting conveyor

- Control circuit voltage will be of 24 Volts.

- PLC will be of Allen Bradley make.

- MOC of inclined conveyor will be MS powder coated.

- MS guard will be provided for pouch packer with Pin type schmershal limit switch.

- Bonfiglioli geared motor of IE3 specification will be used for all drives.

- All contactor will be of siemens make, relay and SMPS will be of Allen Bradley make.

- Electrical panel of IP 65 protection will be used, electrical panel will have one inlet and outlet cooling fan with filter.

- The brake mechanism of the pouch packer will be further strengthened:- Brake motor will be used

- A PLC logic will be built up such that the inspection conveyor and inclined conveyor speed shall be regulated at the time of bags are about to get filled to eliminate pouch getting in between the shutters.

- The linear speed of conveyor, Inclined conveyor and pouch inspection conveyor will aligned to eliminate the pouch jamming and double pouch.

- Electrical drawing, IO list, manual will be provided.

- Cable run way will be provided of MOC :- UPVC.

- Hollow sections of the machine frame will not be used for the distribution of air under any circumstances.

- Exhausts from pneumatic fittings will not be released directly into the atmosphere. They will be collected and piped to a central point where droplets of lubricant may be removed and the exhaust then released safely via a silencer.

- All pneumatic valves will have manual test over-rides. When the valve is solenoid operated then local LED coil status indication will be provided.