An ISO 9001:2015

Certified Company

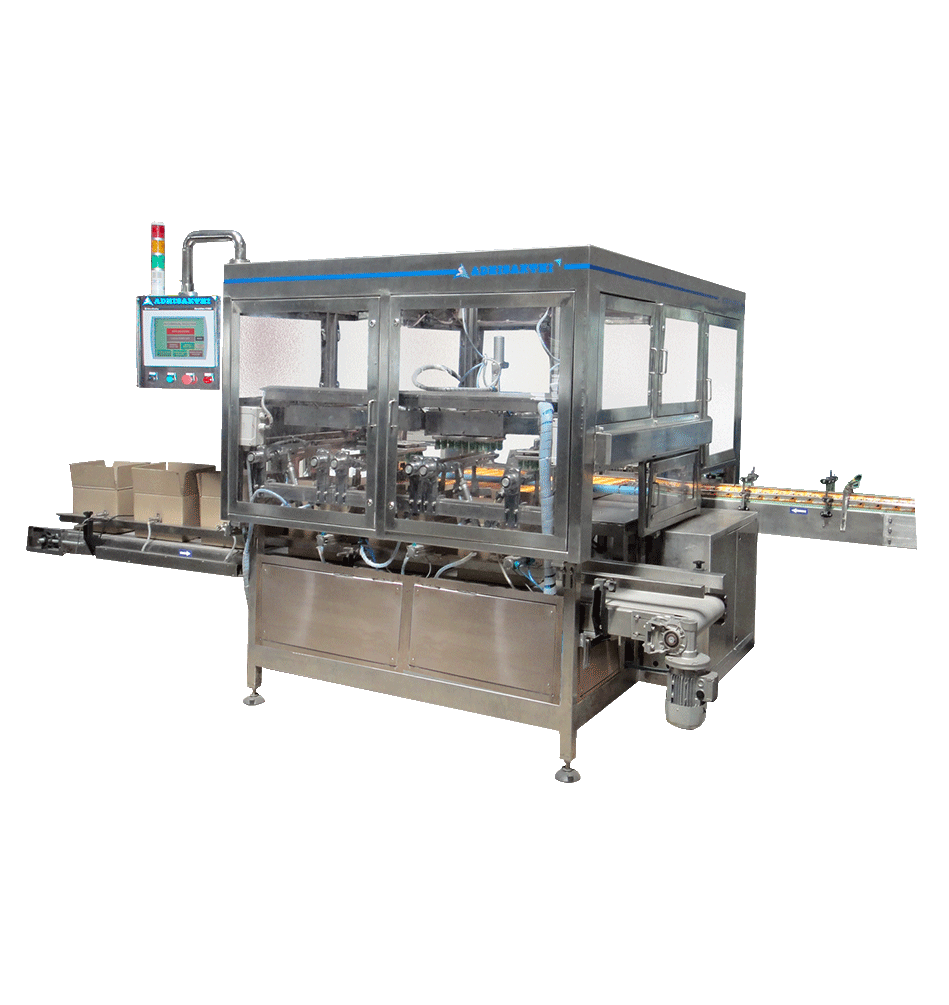

Case Packers - smart Triple Head Model

- The machine is a triple head triple lane infeed with pick and place top load model

- CLD/carton bundles to be opened externally and presented for filling

- Product from end of line is arranged to the matrix size in the triple matrix table

- Matrix layers are picked and placed inside the cld in alternative cycle sequentially

- The cycle repeats till the cartons are filled with top layer and ejected automatically

- Taping needs to be done externally in end of line or supplied at extra cost

- Approx size of the machine : 4300 mm x 1650 mm /effective repeat cycles : Upto 30

- SS base frame and safety covers of 8mm thick polycarbonate with height pads

- PLC : Allen bradley make with HMI support with fault indication system

- Speed depends upon the matrix combination ( effective cycles x matrix size )

- Infeed conveyor to the case packer will be at customer scope or at additional cost

- Light curtains (beam sensors) are not covered in the scope. cost extra if required

- The machine is compatible to pack both bundled soap and individual soap

- Change parts cost is extra as applicable. one size part given with basic machine

- The case erecting and taping machine automatically erect carton and does bottom taping

- The carton/CLD bundles need to be placed on a width adjustable magazine

- Cartons are erected automatically through suction cups and flaps are closed

- Specially designed intermittent motion chain drive picks up the carton for taping/li>

- The machine is suitably designed to accommodate a range of carton sizes

- The machine is sturdily constructed and it is fully covered with ss 304 sheets

- Machine matches to GMP standards and necessary IQ/OQ/DQ certificates are provided

- Pneumatic components are of Festo / SMC make

- PLC : Allen bradley make