An ISO 9001:2015

Certified Company

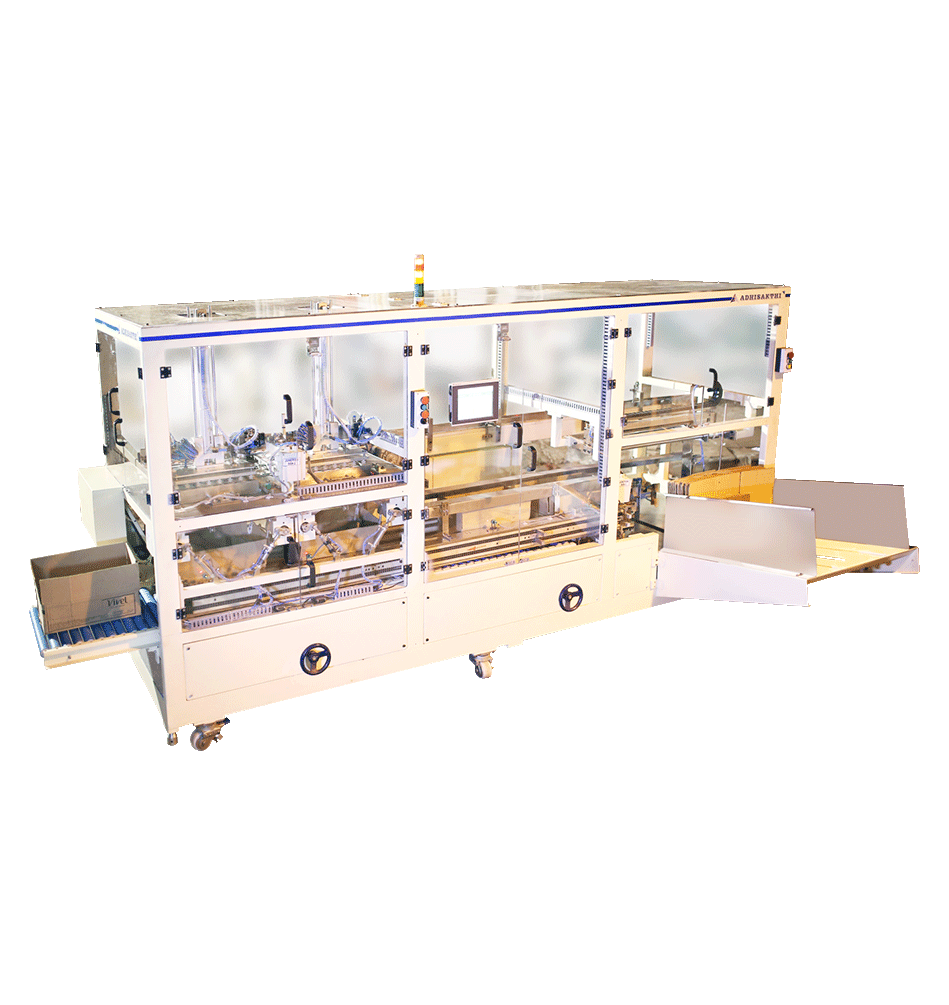

Case Packers - Super Double Head model

- Auto case packer – ACP-PPD-SL is an user friendly cost effective model

- The machine works on the principle of top load pick and place mechanism

- Product from the packing machine end of line is fed in to the case packer

- Based on the matrix size, infeed pusher forms one layer in matrix table

- Carton / CLD is erected manually and bottom flap closed and set for filling

- Once matrix of one layer is completed, vacuum pick up plate picks up the layer

- Product matrix is filled inside the CLD layer by layer till top most

- Upon completion of the top most layer the CLD is ejected out for the main line

- The machine is made of sturdy powder coated ms base and SS 304 contact parts

- Double pick up head – single lane infeed model. Pneumatics : FESTO /SMC make

- Vacuum pick up plate is a change part depending upon the CLD size

- ALLEN BRADLEY PLC with safety covers – safety light curtain is optional extra

- Infeed conveyor belt is covered in customer scope or optional extra

- Speed of the machine : up to 12 pickup x size of the matrix of one layer

- The machine takes up the in feed from single packing machine

| Model | Description | SPEED | FOOT PRINT | CARTON SIZE (L x W x H) mm |

POWER | AIR REQMT | WEIGHT (L x W x H mm ) |

|

|---|---|---|---|---|---|---|---|---|

| (L x W x H) mm | MINIMUM | MAXIMUM | kw | cfm | kgs (apprx) | |||

| TOP LOAD PICK AND PLACE SERIES - SPEED IN CYCLES PER MIN MULTIPLY WITH MATRIX SIZE | ||||||||

| ACP-PPS- ** | SINGLE HEAD SERIES | up to 12 | 1500X1600X1600 | 250X240X150 | 480x340X275 | 0.75 | 25 | 500 |

| ACP-PPD- ** | DOUBLE HEAD SERIES | up to 22 | 3300X2000X1700 | 250X250X200 | 480x350X400 | 1.00 | 45 | 800 |

| ACP-PPS-MD-EX | MODULAR SING. HEAD | up to 12 | 3000X1400X2000 | 250X200X200/td> | 450X300X275 | 1.50 | 30 | 750 |

| ACP-PPD-MD-EX | MODULAR DOUB. HD | up to 22 | 3650x1400x2000 | 250x200X200 | 450x300x275 | 2.00 | 45 | 900 |

| ACP-PPT-MD-EX | MODULAR TRIPLE HD. | up to 30 | 4300X1400x2000 | 250X200x200 | 450X300X275 | 2.00 | 60 | 1050 |

| ACP-PP-TWH-DUP | FOUR HEAD MACHINE | up to 40 | 3750X3200X2000 | 250X250X200 | 480X350X400 | 3.00 | 60 | 1100 |

| ACEP-PPS- ** | ERECTOR SING. HD | up to 12 | 2000X1800X2300 | 250X240X150 | 480X340X275 | 1.00 | 45 | 900 |

| ACEP-PPD- ** | ERECTOR DOUB.HD | up to 22 | 3300X2000X2200 | 250X250X200 | 480X350X400 | 1.50 | 60 | 1200 |

| ACEP-PPS-MD-EX | ERECTOR -S/H MOD | up to 12 | 3000X2300X2000 | 250X200X200 | 450X300X275 | 2.50 | 50 | 1150 |

| ACEP-PPD-MD-EX | ERECTOR-D/H MOD | up to 22 | 3650X2300X2000 | 250X200x200 | 450x300X275 | 3.00 | 65 | 1300 |

| ACEP-PP-TWH-DUP | ERECTOR-F/H MOD | up to 40 | 4750X3200X2000 | 250X250X200 | 480X350X400 | 4.00 | 80 | 1500 |

| ACEPT-PPS- ** | ERECTOR & TPG S/H | up to 12 | 3300X2000X2300 | 250X240X150 | 480X340X275 | 1.50 | 50 | 1100 |

| ACEPT-PPD- ** | ERECTOR & TPG D/H | up to 22 | 4800X2000X2200 | 250X250X200 | 480X350X400 | 2.00 | 65 | 1400 |

| ACEPT-PPS-MD-EX | EREC & TPG MOD S/H | up to 12 | 4500X2300X2000 | 250X200X200 | 450X300X275 | 3.00 | 55 | 1350 |

| ACEPT-PPD-MD-EX | EREC & TPG MOD D/H | up to 22 | 5000X2300X2000 | 250X200X200 | 450X300X275 | 3.50 | 65 | 1500 |

| ACEPT-PP-TWH-DUP | EREC & TPG FOUR HD | up to 40 | 6250X3200X2000 | 250X250X200 | 480X350X400 | 4.50 | 85 | 1700 |

| TOP LOAD - STACKING SERIES FOR NON PICK AND PLACE TOP LOAD MECHANISM | ||||||||

| ACEP-STK | ERECTOR CUM STACKER | Up to 250 pcs/min | 2900x2750x 1700 | 250X200X200 | 450X300X275 | 0.5 | 55 | 900 |

| SIDE LOAD SERIES | ||||||||

| ACEPT-SL-STD* | ERECTOR CUM STACKER | Up to 250 pcs/min | 3400X1300X2000 | 300X200X250 | 500X350X400 | 1.5 | 25 | 600 |

| ACEPT-SL-HISPD* | HI SPEED SIDE LOAD | Up to 450 pcs/min | 4000X1750X2000 | 300X200X250 | 500X350X400 | 2 | 30 | 700 |

| CASE ERECTOR AND TAPING MACHINE | ||||||||

| ACE-TPG | ERECTOR AND TAPING | Up to 12 Ctrns/min | 3000X1700X1600 | 250X240X150 | 480X350X400 | 0.5 | 25 | 400 |