An ISO

9001:2015

Certified Company

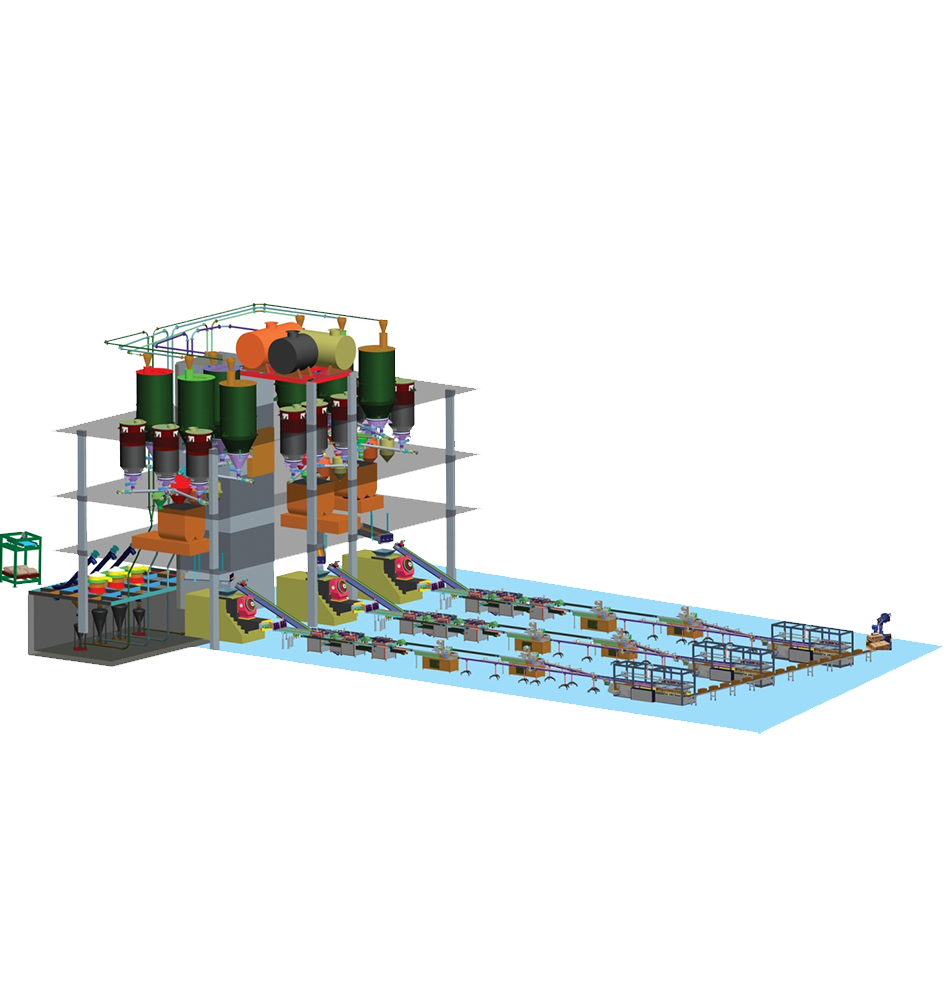

fully automatic batch weighing systems full plant automations

- Ingredients are classified into Major , Small and Minor materials depending upon the proportion of usage in the batches.

- Powders are to be stored in the specially designed platform with suitable capacity Silos.

- Silos are designed for loading powders of three days production.

- Bigger silos are provided with suitable bin vibrators to enable flow of materials.

- Screw conveyors are fitted on the bottom of Silos connecting the weigh hoppers.

- Weigh hoppers of 50 Kgs and 15 Kgs are designed based on the input given by you.

- Suitable Vibratory feeding systems also designed to accommodate the feeding due to space availability.

- All Silos are fitted with Knife gate valve for material control.

- The bulk powder materials such as Carbon and Silica are pneumatically elevated from the ground floor to the storage Silo

- Small and minor ingredients are elevated to the first floor through suitable transfer mechanism and stored in respective Silos

- Two sets of weigh hoppers are provided individually to feed to respective Sigma mixers

- Batch making is programmed through PLC based batch weighing system with recipe management option.

- Complete system is controlled by the PLC through HMI

- Depending upon the sequence of addition, the materials are fed to the weigh hopper through screw conveyor or specially designed tray feeders.

- Feed rate of conveyors are controlled through variable frequency drives or with vibro feeder control system.

- Coarse and fine feed options are provided to maintain accuracy of feeding the powders

- Weigh hoppers are fitted with pneumatically operated wide mouth knife gate valves for instant discharge

- Pneumatic knockers are fitted to ensure powders are completely dispensed into mixers