An ISO

9001:2015

Certified Company

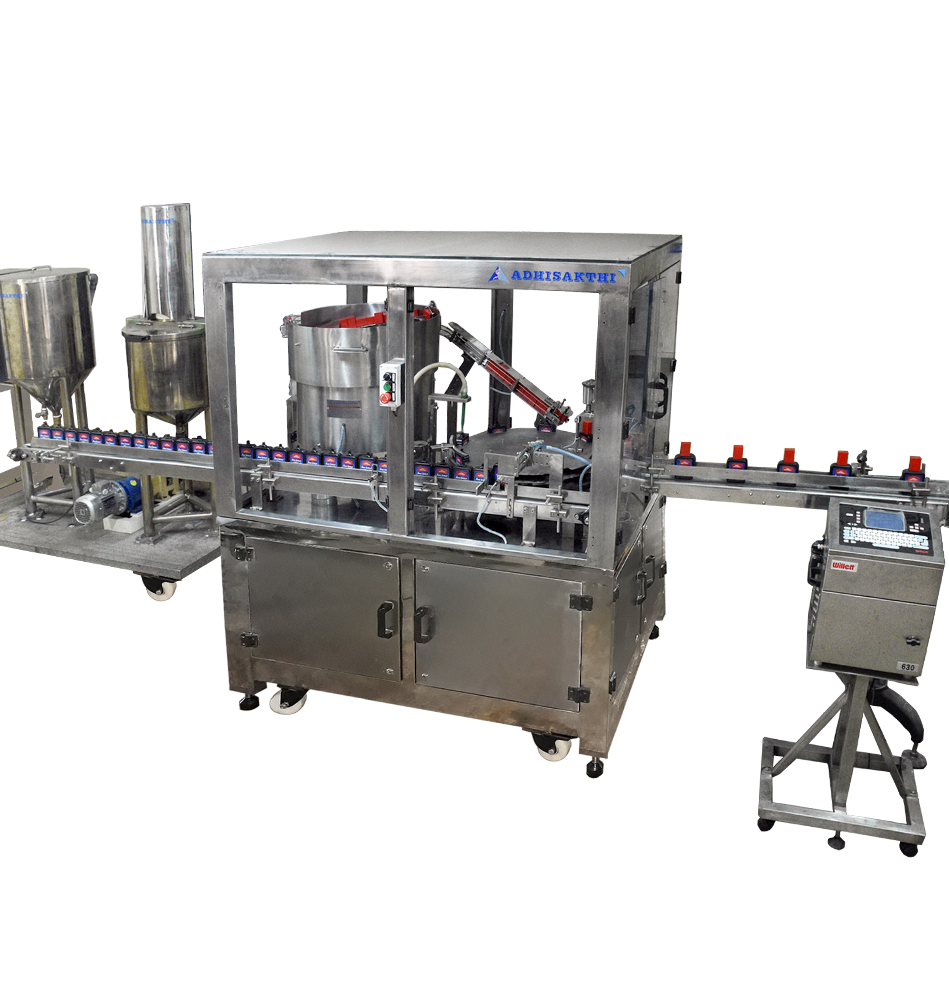

fully automatic Bottle Filling & Capping Machine rotary model

- The machine work on a rotary indexing table of 6/8/10 stations configuration

- Driven through ferguson indexing drive

- Fully PLC controlled

- The machine is compatible for Container filling, nitrogen flushing, plugging screw capping and induction sealing.

- Product contact points will be made of SS 304/SS316/SS316L

- Pneumatic cut off system to ensure no tail over after filling

- All pneumatic Cylinders are of FESTO / SMC make

- Sensors of BANNER/Omron make, No container - No fill - No capping interlocks

- Speed up to 100 pcs /min

- Safety Guards with micro switch interlock

- The machine is compatible to fill, plug and cap eye drops, pharmaceutical products in GMP standards.

- Auto feeding system for Inner plugs

- Auto elevating & orientation system for caps

| Model | Aspro-RBF-40 | Aspro-EBF-120 |

|---|---|---|

| Speed | Up to 40/ head * Depends upon the filling Volume | Up to 20/ head * |

| Indexing Orientation | Rotary | Elliptical |

| No. of Filling Heads | Max. 2 | Max. 6 |

| Contact Parts | SS 304/ 316 | SS 304/ 316 |

| Fill volume | 5 ml to 250 ml | 5 ml to 250 ml |

| Filling accuracy | + 0.5% | + 0.5% |

| Power Required | 1 KW | 2 KW |

| Air Consumption ( CFM ) | 30 | 50 |

| Dimension (LxBxH) | 1500x1500x2100mm | 855x500x2149mm |

| Weight (Approx.) | 600 kgs. | 1300 kgs. |

| On-line Capping | Optional | Optional |

| Final Packing Conveyor | Optional | Optional |

| * Depends upon container shape, product, fill volume, container orifice, etc | ||