An ISO

9001:2015

Certified Company

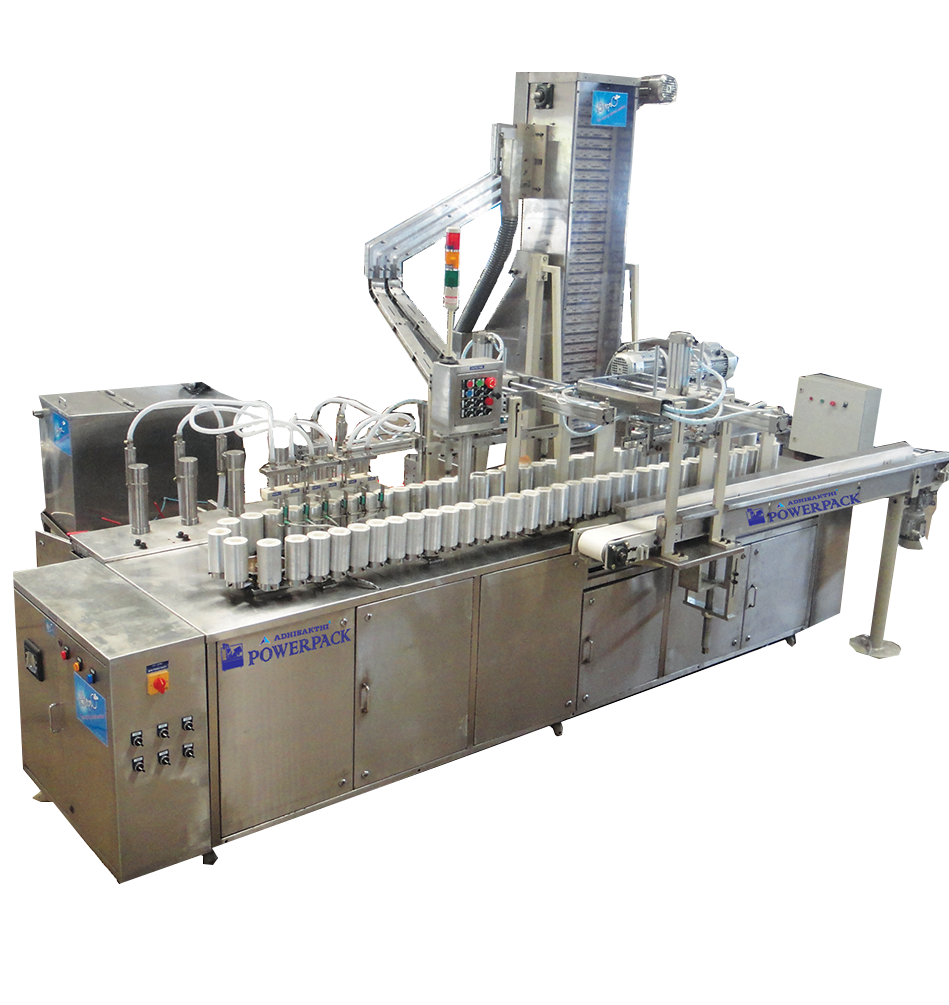

high speed puc based slim Containers Filling & Capping Machine

- The machine runs on elliptical run way intermittent motion mechanism with conveyor chain system

- Containers are held in PUCs for filling and Capping operations

- Highly suitable for flat bottom and odd shaped plastic containers which are not stable to travel on a flat conveyor

- FERGUSON INDEXING SYSTEM is used to achieve accuracy of indexing and higher speed per nozzle

- Speed up to 120 pcs per minute

- Higher productivity rates

- Fully automatic filling, cap elevating, capping, ejection and online inspection system

- Direct link up provision for online coding and labeling requirements

- Occupies very less space

- Filling accuracy +/- 0.5 %

- Product contact parts are made of SS 316L and Covers of SS 304

- Unique and simple change over system

- Automatic pick and place ejection mechanism. (Auto depucking)

- Option of 4 Heads & 6 Heads are available.

- Fully PLC controlled with HMI Panel.

| Model | Aspro-RBF-40 | Aspro-EBF-120 |

|---|---|---|

| Speed | Up to 40/ head * Depends upon the filling Volume | Up to 20/ head * |

| Indexing Orientation | Rotary | Elliptical |

| No. of Filling Heads | Max. 2 | Max. 6 |

| Contact Parts | SS 304/ 316 | SS 304/ 316 |

| Fill volume | 5 ml to 250 ml | 5 ml to 250 ml |

| Filling accuracy | + 0.5% | + 0.5% |

| Power Required | 1 KW | 2 KW |

| Air Consumption ( CFM ) | 30 | 50 |

| Dimension (LxBxH) | 1500x1500x2100mm | 855x500x2149mm |

| Weight (Approx.) | 600 kgs. | 1300 kgs. |

| On-line Capping | Optional | Optional |

| Final Packing Conveyor | Optional | Optional |

| * Depends upon container shape, product, fill volume, container orifice, etc | ||