An ISO

9001:2015

Certified Company

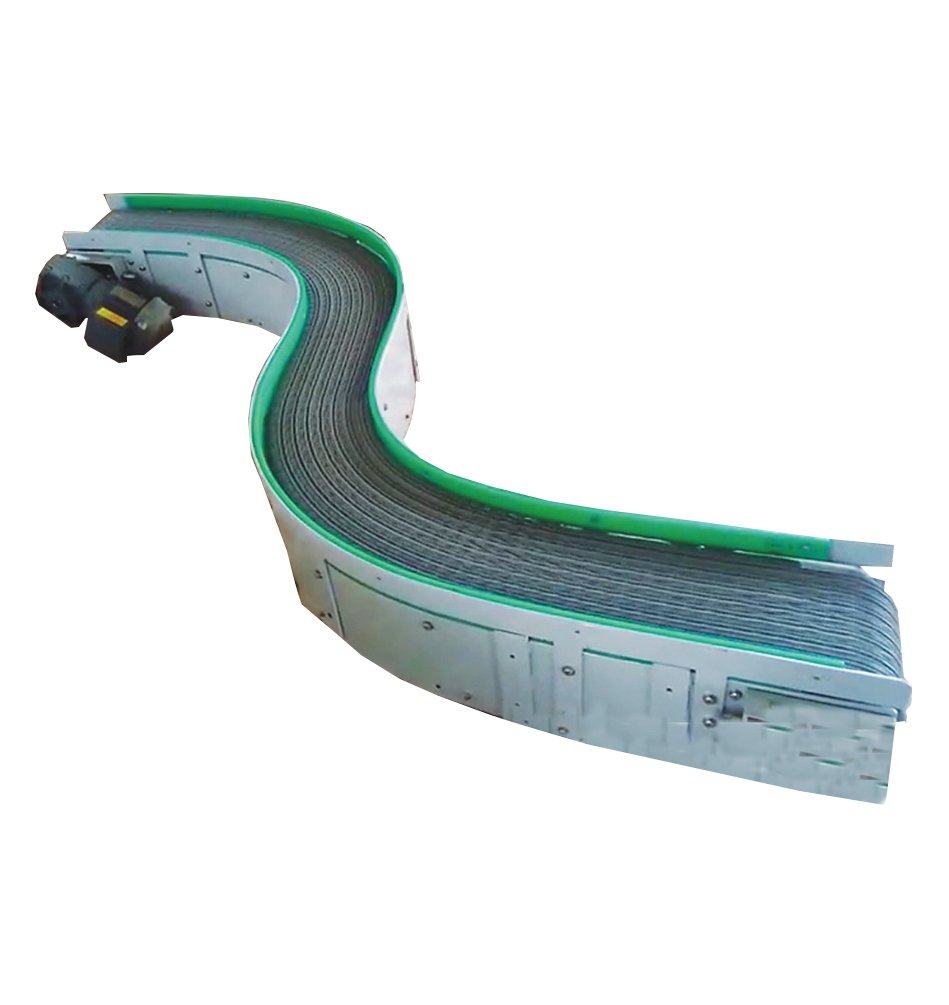

Material Handling Systems - Modular Flex Link Conveyors

- Modular belt conveyor are a middle ground between belt conveyors and chain conveyors. A modular belt consists of individual plastic modules usually linked together with joint rods. This modular belt is driven by chain spockets; the base frame of the conveyor is constructed on standard profile supports.

- The modular belt makes it possible to accept hot workpieces or workpieces with sharp edges. Furthermore, large conveyor widths can be implemented without high pre-tensioning of the belts. However, in contrast to chain conveyors, this design is less maintenance-intensive and is a technically simpler solution. These systems are frequently used as cooling lines, since the chain modules can be designed to be permeable to air.

FEATURES

- For transporting piece goods without specific requirements regarding the product’s position, orientation or the product geometry

- High belt loads possible

- Positive drive mechanism eliminates slippage and makes it suitable for wet applications; permeable chains also available

- Stable chain travel regardless of the length/width ratio

- Maximum usable width with low total width

- Lateral movement of product

- Belt is guided to eliminate lateral deviation

- Chain material is highly resistant to wear and abrasion, making it suitable for high temperatures, contact with chemicals or food, etc.

- Variable track layouts with just a single drive, different speeds at no additional cost

- Accessories such as side boards and transverse cleat profiles available

- Chain can be opened for easy disassembly and for replacing/combining chain modules.