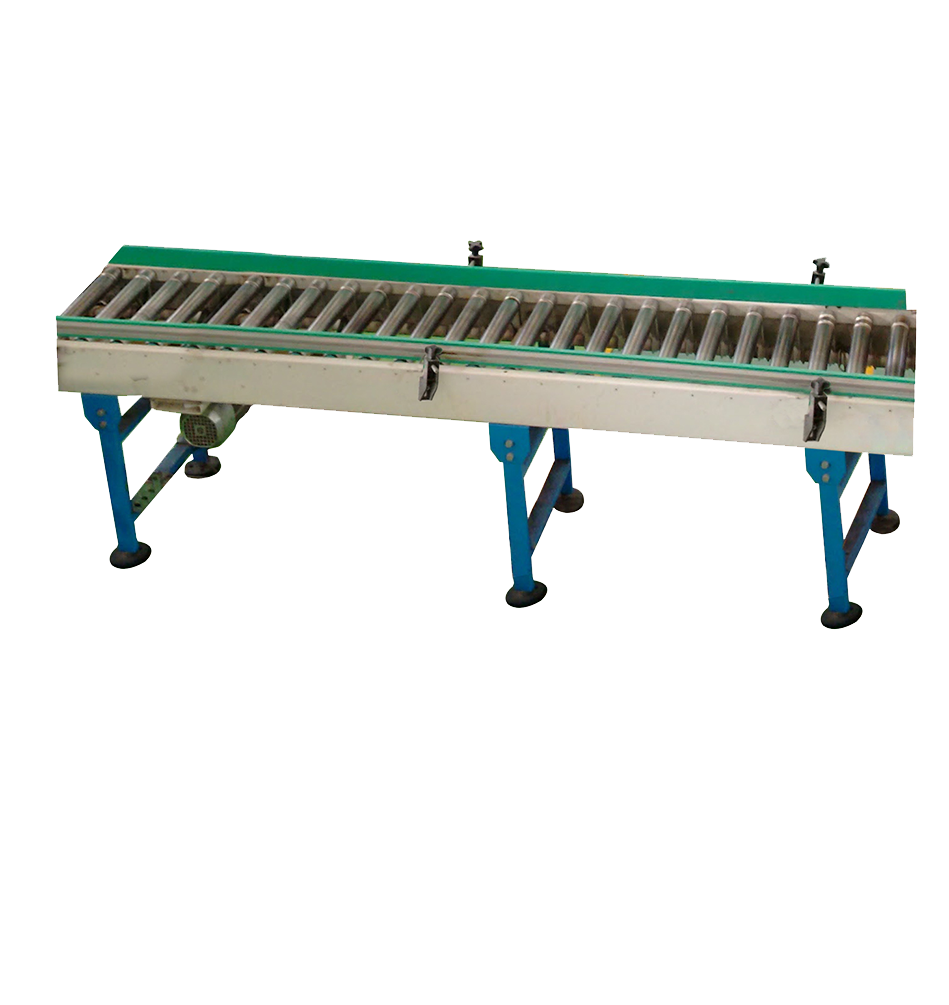

Material Handling Systems - roller conveyors

Roller Conveyor is a type of conveyors with a series of rollers supported in a frame over which objects are advanced manually, by gravity, or by power.A roller conveyor is a conveyor that consists of a series of parallel rotating bars that move goods along to their end destination. Roller conveyors are used in environments like warehouses and manufacturing facilities. These conveyors are containing sprocket at one terminal and a bearing housing at other. A roller shaft runs through the rollers, which are mounted on the extruded aluminum rails.

Roller conveyors are the proper choice when you need to side load, push off, accumulate a product or adjust pressure on carrying rollers. Roller conveyor types are chain driven, belt driven, line shaft driven, accumulation, or non-powered (gravity). Using roller conveyors instead of slider bed conveyors adds versatility to the type of transfers, diverters and stops that can be used in a system. Rollers are available in mild steel, galvanized, plastic or stainless steel.

A lineshaft roller conveyor or line-shaft conveyor is, as its name suggests, powered by a shaft beneath rollers. These conveyors are suitable for light applications up to 50 kg such as cardboard boxes and tote boxes. A single shaft runs below the rollers running the length of the conveyor. On the shaft are a series of spools, one spool for each roller. An elastic polyurethane o-ring belt runs from a spool on the powered shaft to each roller. When the shaft is powered, the o-ring belt acts as a chain between the spool and the roller making the roller rotate. The rotation of the rollers pushes the product along the conveyor. The shaft is usually driven by an electrical motor that is generally controlled by an electronic PLC (programmable logic controller). The PLC electronically controls how specific sections of the conveyor system interact with the products being conveyed.

Advantages of this conveyor are quiet operation, easy installation, moderate maintenance and low expense. Line-shaft conveyors are also extremely safe for people to work around because the elastic belts can stretch and not injure fingers should any get caught underneath them. Moreover, the spools will slip and allow the rollers to stop moving if clothing, hands or hair gets caught in them. In addition, since the spools are slightly loose on the shaft, they act like clutches that slip when products are required to accumulate (stop moving and bump up against each other. i.e. queue up). With the exception of soft bottomed containers like cement bags, these conveyors can be utilized for almost all applications.

- Roller conveyor is conveys carton boxes of different sizes in packed condition

- Width of the roller : 410 mm and Diameter : 50mm

- The rollers are powered by the geared motor drive of 5 Hp bonfiglioli make drive to the rollers are given through PU bobbins

- Base structure MS powder coated and rollers are supported on bearings conveyor system provided with SS guides

- It consists of two conveyor each having dimension: 7.5 M & 7.5 M