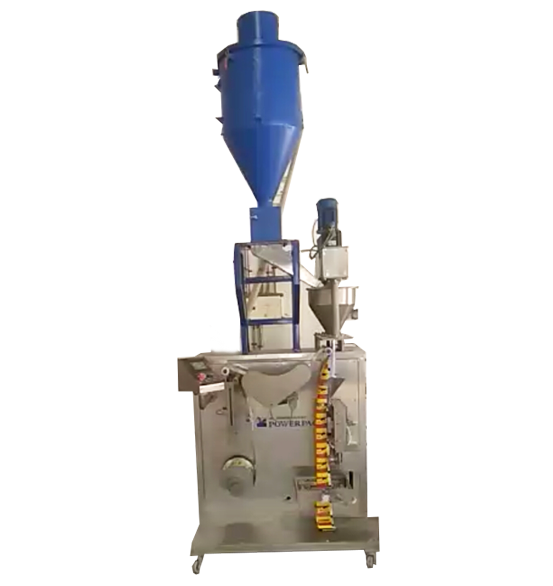

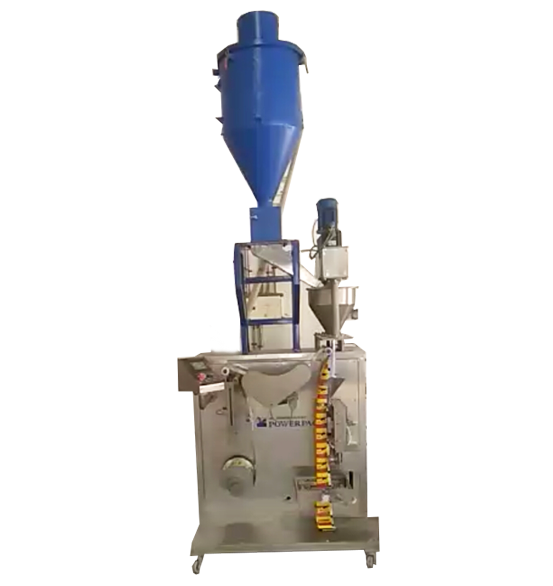

Vertical Form filling & sealing machine fitted with servo based auger Dosers suitable for non-free flow powders

All contact parts are made up of SS304 with taper hopper enabling easy flow

Driven by set of stirrer of Bonfigioli geared motor speed upto 40 pcs/min

The machine consists of base frame fitted with draw down belt system

Speed of the machine reaches Up to 30 - 35 per min dep upon pouch length & product

Fully PLC controlled. (Allen Bradley/Omron) mounted on dust proof cabinet

PID temperature controllers for constant temperature ensuring proper sealing

Easily replacable film roll mounting to hold 15 kgs driven by unwinding motor

Cross sealer and longitudinal sealers are pneumatically operated

Batch cutting provision through perforated pneumatic blades

One forming collar & basic set of Rotary Cup will be provided - Change parts extra

Print scanner assembly to control the clutch brake drive system

Electrical power required: up to 4 KW / Air consumption: 10 CFM @ 6 bar pr.

Machine size: 1800 mm x 1400 mm x 2000 mm; filling range: Upto 100 Gms

All pneumatic components are of FESTO / SMC make