An ISO 9001:2015

Certified Company

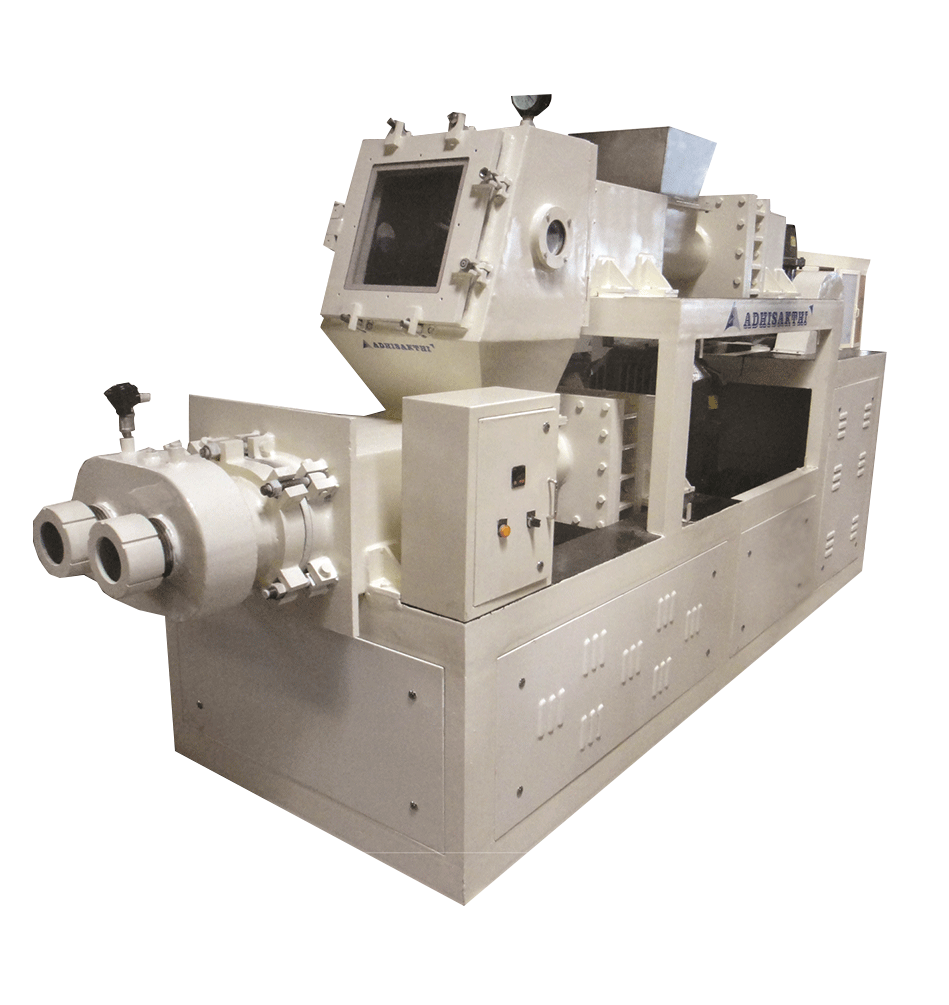

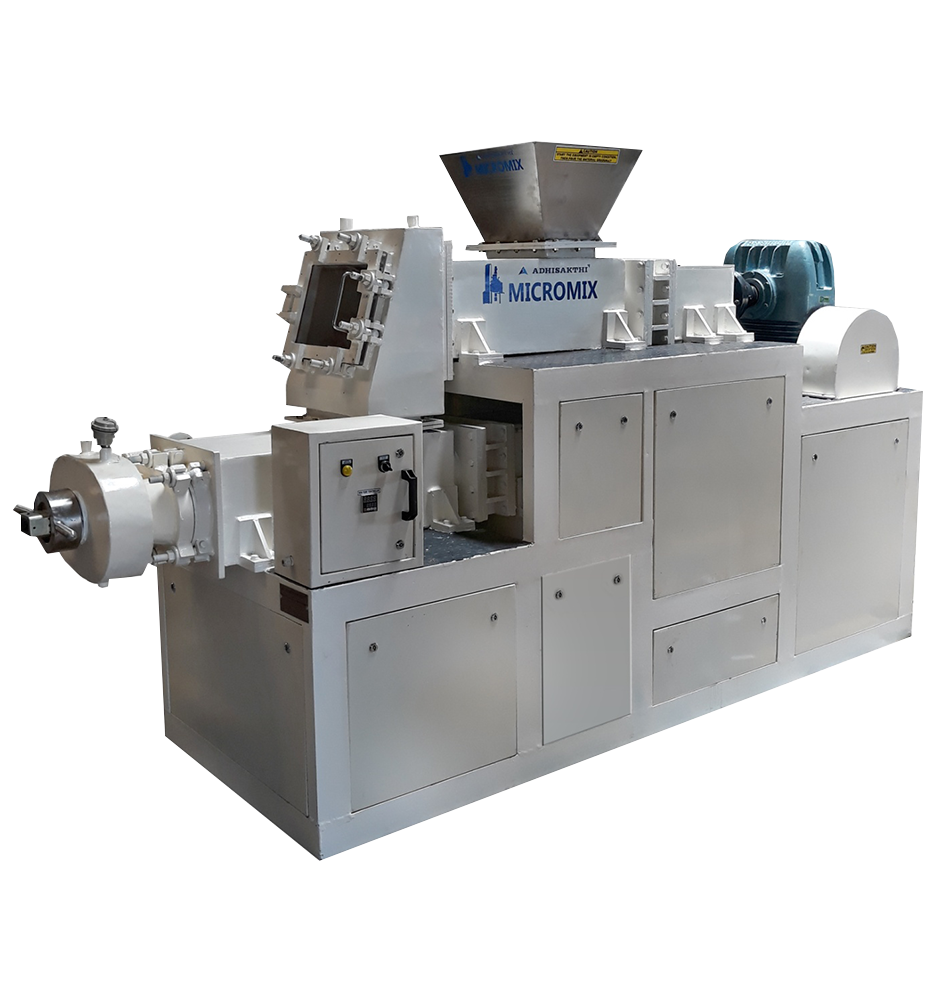

twin worm duplex Vacuum Plodders

- Twin worm duplex vacuum plodder refines the soap mixture to smooth bars

- Duplex plodder comprise of pre plodder and final plodders driven individually

- The mixture is extruded by twin screws in pre plodder orifices of noodle plate

- Rotary SS shredders on worms cut equal lengths noodles & pass to vacuum chamber

- Vacuum chamber connects the pre plodder and final plodder with openable lid

- Final plodder compacts the soaps to a fine finished bar by its conical jacket mouth

- Twin cylindrical barrel made of SS 304/ MS and precision machined onners

- Barrel is constructed with thick back flanges to match to the twin output gearbox

- The barrel is jacketed and pressure tested for chilled water circulation

- Twin screws are of 300 mm dia each with left and right flutes with reduction pitch

- Screws are solidly casted SS 304, X ray tested with flights for positive extrusion

- The worm shaft is supported at the end through heavy duty thrust bearing housing

- One motor at the top stage and another motor at the bottom stage

- Double extrusion mouth with heating system